Classic tunnel pasteurization process

Substrate processing tunnel for oyster mushrooms the production is currently the most resource-saving technology ensuring stable quality of substrate blocks and high mushrooms yield.

The raw material for the production of the substrate is a multicomponent mixture of cereal straw and hay (with the possible addition of sunflower seed husk), which is humidified after grinding and stored at a site or in a silo. After rehandling this mixture is placed in a tunnel for further processing.

The tunnel itself is a thermally insulated chamber where raw material is steam

pasteurized. After cooling of the biomass it is ready for inoculation – adding mycelium into substrate bags. The purpose of such treatment of raw materials is to eliminate foreign microbial flora (fungi and bacteria) as well as partial decomposition of plant matter for a better development of oyster mushroom mycelium.

Continuous substrate quality control (nitrogen content, humidity, pH) performed by a qualified technologist enables to avoid spoilage and increase yields.

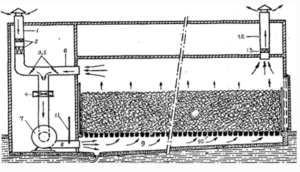

Steaming chamber (Figure 1.) – a room with two gates on opposing sides – one for loading and one for unloading materials. The walls, the ceiling and the floor must be insulated using plastic foam or polyurethane foam. In the chamber there is a pallet, in where steam is supplied and the mesh floor on which the raw material is loaded. The vapor is cycling through the raw material by the ventilation system, with fresh air supply system and discharge valve. To eliminate the human factor and improve processing consistency automated process control system is used in the steam chamber. To produce steam the steam generator is used – powered by gas or solid fuel.

Fig.1. Tunnel construction.

1- ventilation air-shaft; 2-microbial air filter; 4- air cooling element; 3,5-regulating valves for external and internal pressure; 6-intake duct for air recirculation; 7-fan; 8-diffuser; 9 plenum chamber; 10-slotted tunnel floor; 11, steam supply pipe.

The tunnel can be constructed in different sizes and capacities starting from 2-3 tons to 40 tons of substrate. For the production line you will a premise of 100 to 230 m2 in area, depending on the number of substrate blocks produced. It should be about 6 m in height (at least in the part where the tunnel is located) and there should be a canopy of about 100 m2 for substrate pretreatment.

In case of 20-ton tunnel operation once in 8 days it is possible to produce a substrate for the cultivation of 20 tons of mushrooms per month, operation every 4 days will provide materials for the cultivation of 40 tons oyster mushrooms per month. Hydraulic presses are used for substrate blocks formation.

Necessary equipment:

Straw cutter (strawmill)

rotating drum for water steeping (preferably)

steam generator

conveyors or a tractor with a grapple

Hydraulic press for substrate block formation

Ventilation equipment and automation unit for the tunnel

Clean zone ventilation equipment

Boiler for workshop heating and heating water for plantmaterial steeping process Mini tractor for unloading the substrate in a clean area (desirable).

The substrate preparation process according to the classical technology begins with a long process of straw moisturizing in a special area. Straw humidity before loading into the tunnel should be 74-75%. During substrate moisturizing material must undergo the processes of complete hydration of all natural microflora spores. This leads to the exit of all microorganisms from their inactive dormant state.

The next step – is a substrate loading into the tunnel. Ideal option is the use of retractable telescopic conveyor. Basic requirements for filling the tunnel are height of the substrate layer, which should be no less than 1.5 m and not more than 2.2 m, and the uniformity and speed of material filling. Straw is a fairly loose substrate, so it is necessary to have in mind that straw shrinkage can be within half a meter. Per 1 m2 you can load up to 1,000 kg of moistened straw. The upper level of straw must straw must be no less than 1 m from the ceiling and the straw must not be in contact with the tunnel gate. For this purpose, special channels are created before the gates in which the supporting board shield are mounted.

After loading with substrate the the tunnel is closed and ventilation is activated in order to equalize the temperature in the mass. The substrate is steam heated, which is fed mixed with air. Calculated amount of steam is 20-25 kg per hour per 1 ton of substrate and 200-250 cubic meters of air per hour per 1 ton of substrate.

Temperature treatment at 67-72°C under long exposure maximize straw nutrient substrate activity for oyster mushroom mycelium.

The process is well controlled, so the substrate is uniform in quality. The technology involves the use of mechanization, which in turn can be considered as the basis for creating a sufficiently large-scale substrate production for growing oyster mushrooms.